Making Process of Computer Circuit Boards

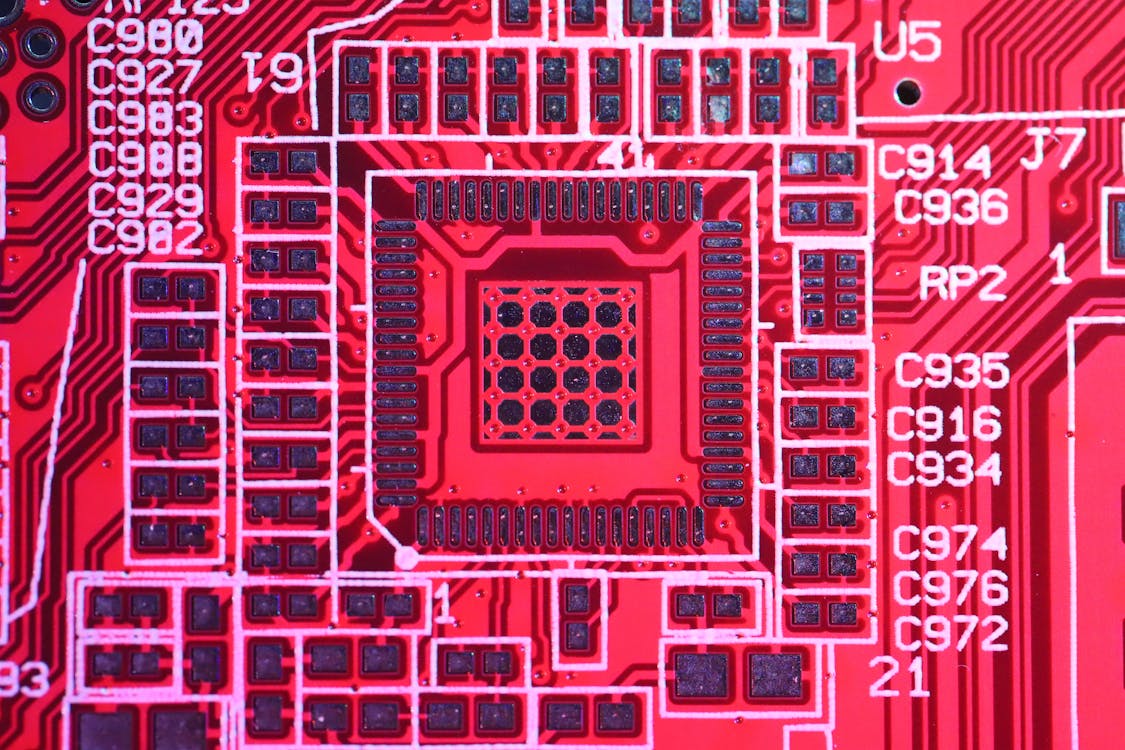

A circuit board is a piece of plastic with copper tracks that hold electrical components, such as transistors, diodes and integrated circuit chips. The components are soldered to the traces using heated solder wire that holds them in place and provides a secure electrical connection. The board's size, shape and layout determine its function. Computer circuit boards are manufactured to meet a variety of requirements and can be simple or complex.

How do circuit boards work, A printed circuit board is designed by an electronic design automation (EDA) system, which translates schematic diagrams into a layout on the PCB's surface. The resulting circuit boards are made of two or more layers of dielectric composite materials that are laminated together with a thin copper coating on one side. The copper is deposited by chemically plating the bare laminate with metal ions. Holes, used for insertion of through-hole components and to connect the various layers of the board, are also plated with copper. The holes are drilled with drill bits made of solid coated tungsten carbide, rather than high-speed steel, which would quickly dull and ruin the board's copper layer.

The first PCBs were fabricated in the early 20th century, when German inventor Albert Hanson patented a flat conductor for a multilayer insulating board that had conductors on both sides. These were the forerunners of today's plated through hole construction. Those types of PCBs were primarily used in consumer electronics such as alarm radios, Atari game consoles and cordless phones.

In the 1960s, as the U.S. ramped up space exploration and JFK-mourning boomers prepared for the British Invasion, two innovations greatly improved PCB technology. The first was a plated through-hole technology, a Hazeltine Corp patent that allowed close spacing of components without risk of misalignment. The second was a surface mount technology developed by Paul Eisler, a Jewish inventor who immigrated to England from Austria to escape Nazism. This permitted a simpler, cheaper, more reliable circuit board design.

Computers and other electronics become more sophisticated over time, and their circuitry must be made smaller to fit into small devices such as cell phones. As the devices get smaller, however, they also become more difficult to repair or modify. It's more challenging to swap out a fried chip than it is to replace a whole motherboard.

The Northbridge is the most important chip in a PCB because it handles all of the information that goes to and from the CPU. It is responsible for balancing data, energy, speed, temperature, current and other parameters. To keep the Northbridge from overheating, it must dissipate heat efficiently. A heat sink is often installed on the Northbridge.

A specialized process, called subtractive or additive, is used to form the pattern on the PCB that will be etched into a blank copper-clad laminate. The bare laminate is covered with photosensitive film, which is exposed to light to create a pattern on the film. Then the unexposed areas of the film are sensitized by a bath with potassium permanganate or other chemicals that make them capable of bonding with metal ions. The resulting patterns are then either removed by mechanical means, such as a chemical etch, or added by a full additive process.